Baldness and patchy spots on the beard is one of the most disappointing and demoralizing feelings. A patchy beard is characterized by your beards unevenly growing.

You shouldn’t be ashamed or stressed about your patchy beard. There are numerous beard styles and tips you can use to hide or improve the look of your patchy beard.

Here are a couple of tips recommended for people who desire beard styles for patchy beard:

- Grow your beards long – Growth of long beards is one of the ways you can use to identify where patches are forming on your beard. This will guide you on the patchy beard style to choose.

- Regularly trim your beard – Numerous patchy beard styles recommend regular trim. A regular trim is one of the ways you can minimize the appearance of a patchy beard. There is always a beard style that can be used to hide the patchy look on your beard.

- Cleaning up the lines – A patchy beard brings out a messy look. Cleaning up the beard lines on both sides brings out a neat and professional look. Your sideburns should be properly trimmed to hide the patchy look.

- Deal with the uneven cut – Patchy beard is characterized by uneven growth of beard on the beard. Seek the help of your barber can help deal with the uneven cut.

Coolest Patchy Beard Styles

Here are some beard styles for a patchy beard worth checking out:

1. Patchy Beard with Low Fade Haircut

This haircut is characterized by two fade out layers. Your hair should gradually fade out moving towards the sides. Swiftly, trim the hair around your mid head up to your desired length.

Your fringe hair should be longer when compared to your mid head hair. Form a second fade layer on both sides of the head. This haircut insists that your beard should conjoin with your hair.

Consequently, your sideburns should be equal in terms of length with your sideways hair. You should also grow a moustache. Trim low your beards so that they suit both official and outing events.

2. Thin Strap Beard

A thin strap beard efficiently hides the patchy look on your beards. Hair around your mid head should be longer when compared to that on both sides of the head and on the back.

Additionally, a thin strap beard haircut doesn’t encourage going bald at any point on the head. Systematically come up with a fade out look on your head.

Here, you are free to draw a cut on your hairline. Moving on, your beard should conjoin with your hair. Afterwards, form a thin line with your beard.

3. Stubble Patchy Beard

Here, your hair should slowly fade going downwards. Consequently, your beard should attain a uniform look in terms of length. The last fade out look should be equal length with your beard.

Your fringe hair should be directed towards the back. Ensure your hair conjoins with your beards. A stubble patchy beard doesn’t encourage cut on any part of your hairline.

Swiftly trim your beard to attain a uniform look. That’s not all; a stubble patchy beard encourages the growth of a moustache.

The look of this haircut makes it suit any function. It can be casual or official.

4. Patchy Beard with Handlebar Mustache

Patchy beard with handlebar moustache encourages the growth of moustache. All your hair apart from your fringe and mid head hair should be trimmed low.

Afterwards, direct your fringe and mid head hair towards the right side of the head. Move on and style your moustache to bring out an amazing look. Trim low the rest of your beard.

This haircut gives you the freedom of deciding if your hair should conjoin with your beard or not. This beard style sets the platform for other delicate styles later in the future.

5. Dark Beard with Sculpted Moustache

A dark beard with a sculpted moustache is characterized by long hair with a beard. Trim low hair on both the right and left sides of the head. Direct your fringe and mid head on both sides of the head.

A large fraction of your hair should be directed on the right side of the head. This hairstyle insists that your beard conjoins with your hair.

Consequently, you should grow a moustache. Trim and draw a cut on your beard so that your moustache conjoins with the rest of your hair.

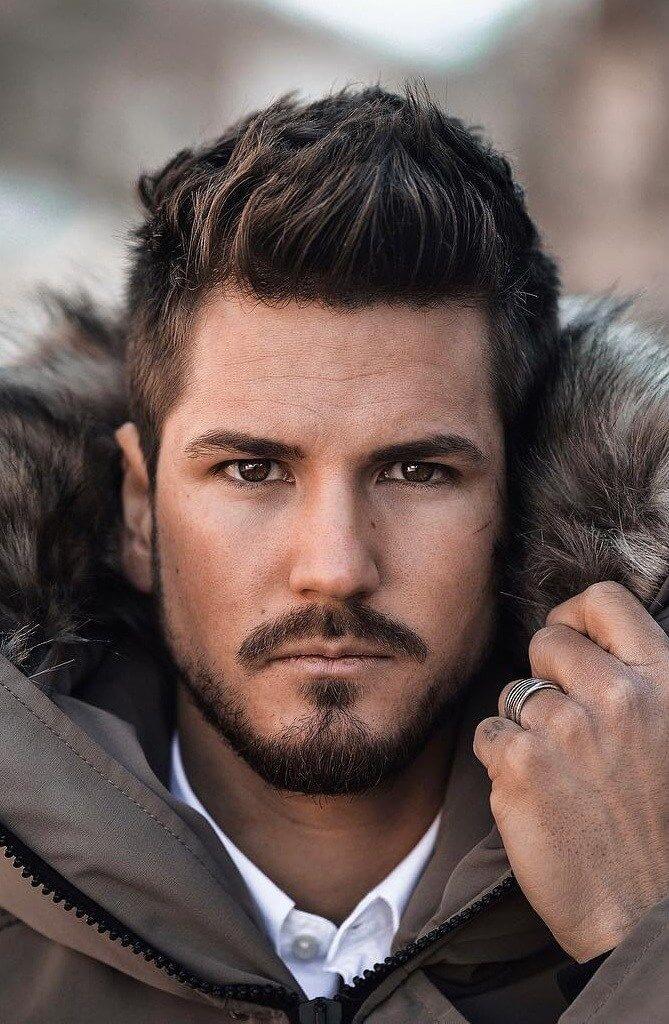

6. Patchy Beard with Short Hair

A patchy beard with short hair brings out a Mohawk look. Men with coarse hair are the ideal candidates for this haircut. Comb your mid head and fringe hair upwards before trimming its edges to attain your required length.

Trim your sideways hair on both sides and hair on the back to attain a uniform look. This haircut doesn’t encourage baldness. Give cut on both sides of the head.

This should extend up to your beard. Your moustache should be separated from your remaining beard but properly cleaned on its edges.

7. Patchy Beard with Long Hair

This patchy beard style aims at bringing out both your long hair and properly trimmed patchy hair. This haircut hides the uneven growth of your patchy beard.

Rest your front view hair on either the right or left side of the head. Here, your beard should conjoin with your hair. However, it should be low in terms of length when compared to the hair.

Shape your beard on both sides of the head to bring out an amazing look. Finally, your moustache should conjoin with the rest of your beard.

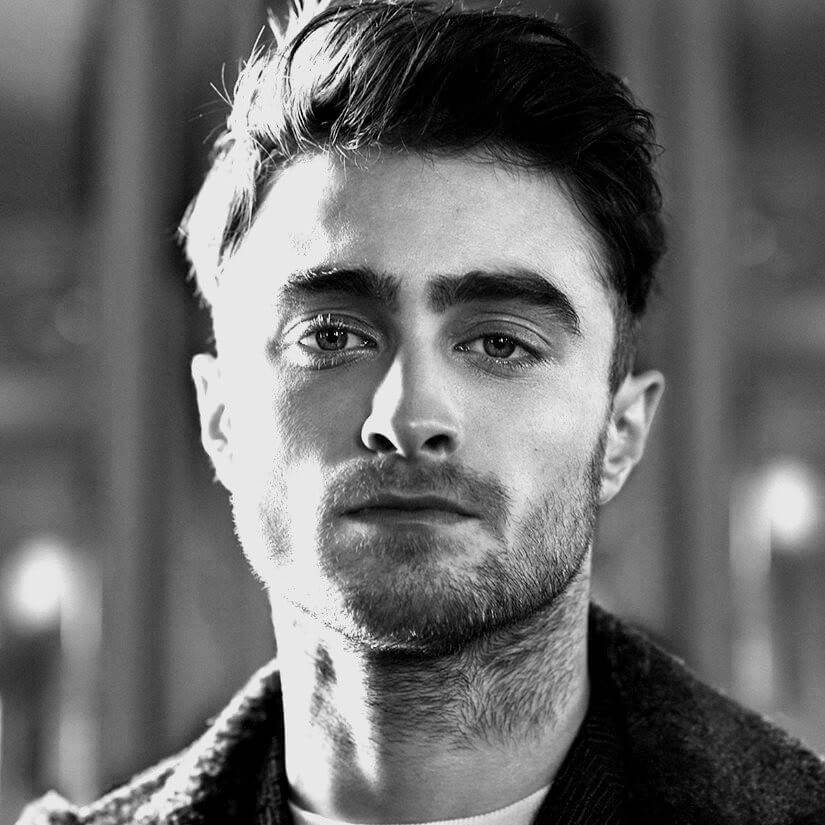

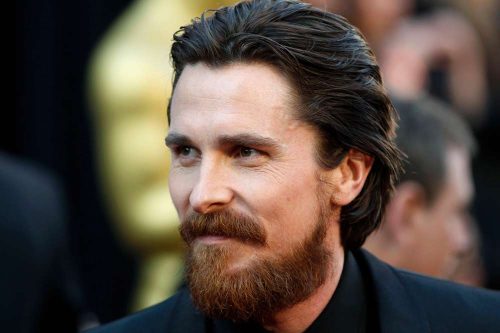

8. Patchy Beard with Sleek Back Hair

This is one of the classical beard styles on this list. Here, your hair should attain two faded layers. One layer should be hair around your mid head.

The second layer should be hair on both sides of the head and that on the back. Direct your fringe and mid head hair towards the back of the head. Ensure your hair conjoins with your beard.

Here, your beard should increase in length stretching downwards. Your moustache should conjoin with your beard. Don’t forget to trim the edges of your beards to bring out a neat look.

9. Patchy Beard with Messy Hair

Give your entire hair a layered and curly look. Move on and rest your fringe hair on your forehead. The remaining front view hair should rest on both the right and left sides of the head.

Here, your hair should conjoin with your patchy beard. Trim low your beard before styling it to attain an amazing look.

Your sideburns should be longer when compared to beards on other parts. Beards on other parts should be equal in terms of length.

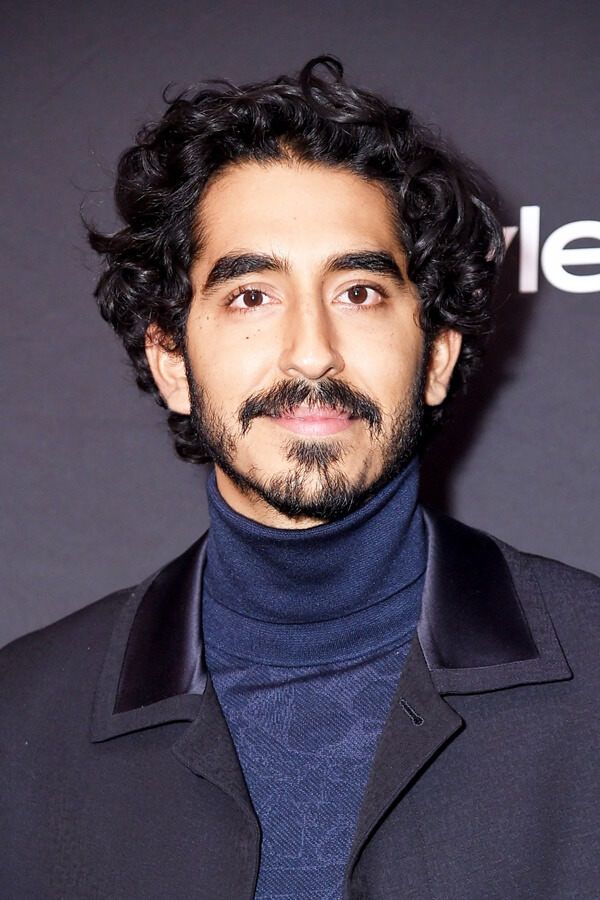

10. Patchy Beard with Curly Hair

Start off by giving your entire hair a curly look. This patchy beard haircut aims at trimming off some beard on both sides. This is mostly the region beard on one side hasn’t grown at all.

This is one of the numerous haircuts on this list that bring out both official and casual looks. A patchy beard with curly hair also encourages the growth of a moustache.

Your moustache should conjoin with your beard on both sides of the head. Commence and trim low your beard. This brings out a neat look. Try out this amazing haircut.

11. Patchy Beard with Goatee

The length of your beard should be adjacent to that on both the right and left sides of the head. That’s not all; your moustache should be styled.

It should also conjoin with the rest of your beard. Hair around your mid head should be longer when compared to that on both sides of the head.

Apply gel to the hair around your mid head before directing it towards the back. Proceed and ensure hair on both sides of the head conjoins with your beard.

12. Long Patchy Beard

A long patchy beard focuses its attention on your beard. This haircut emphasizes the growth of a lengthy beard. Consequently, you are encouraged to grow a long moustache.

Trim your hair low throughout the head. It’s up to you to choose the size of hair to attain on the head. Give cut on the edges of your beard to bring out an organized look.

The look of your beard should be the same on both sides. Lastly, your moustache should conjoin with your hair on both sides.

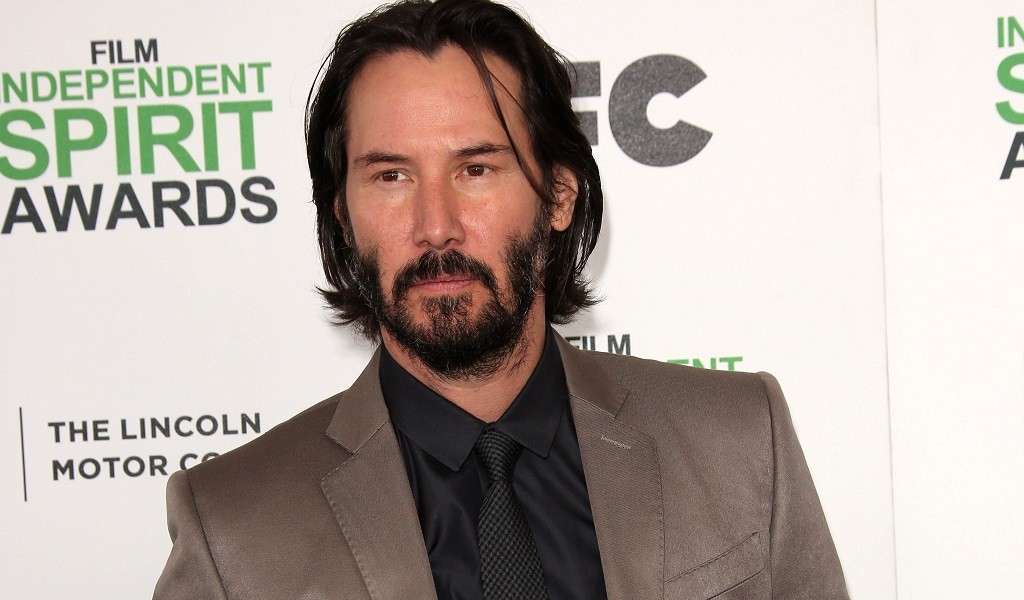

13. Patchy Beard with Long Goatee

This haircut directs its attention to your beard. Men with long beards are the ideal candidates for this haircut. Here, you are free to give your beard a blend of black and gray look.

Your beard should systematically increase in length going downwards up to your chin. Consequently, your moustache should conjoin with your beard on both sides of the head.

That’s not all; your beard should conjoin with your sideways hair on both sides of the head.

14. Patchy Beard with High Faded Sleek Back Hair

Here, your beard shouldn’t conjoin with your hair. However, your moustache conjoins with the remaining hair. Men who love this haircut will attain three different layers.

The hair on your mid head should be longer when compared to that on other parts of the head. Move on and comb your fringe and mid head hair towards the back of the head.

Form the second faded layer on both sides of the head and on the back. Afterwards, a section of hair should be completely bald.

15. Full Patchy Beard with Side Part Hair

Men with long beards all over the face are the ideal candidates for this hairstyle. Your beard should conjoin with both your hair and moustache.

Here, you should grow your patchy beard long to hide the patches. The gray look on the head brings out an amazing look throughout the head. Draw a line on the right side of your mid head.

This line makes your fringe and mid head hair be directed on the left side of the head. Trim low your sideways hair before combing it downwards.

16. Patchy Beard with Funky Hair

This is one of the urban haircuts on this list. Patchy beard with funky hair is characterized by two fade out layers. Consequently, your beard should conjoin with your hair. Trim hair around to mid head to attain your desired hair length.

Choose a spot on both sides of the head and on the back to form the second fade out layer. The hair length of the second layer should extend up to your beard.

17. Thick Chin Strap Beard with Pompadour Hair

Your hair should conjoin with your beard. Similarly, your moustache should conjoin with your beard on both sides.

You will need the help of an experienced barber to attain this amazing and neat haircut. Here, your hair should systematically fade out towards the back and on both sides of the head.

Direct your fringe and mid head towards the back of the head. The fade out look should be attained up to where your beard commences.

18. Gray and Black Patchy Beard with Messy Hair

Ensure your beard conjoins with hair on both the right and left sides of the head. This hairstyle also encourages the growth of moustaches.

In fact, your moustache should conjoin with hair on both sides. A layered and curvy look is the simplest way of attaining a messy look.

Move on and trim your sideways hair on both sides of the head. Hair around your mid head should be longer when compared to that on other parts of the body.

19. Short Patchy Beard

A short patchy beard haircut encourages your beard to attain a low trim. A low trim helps hide the patchy look on your beard. The low trim brings out a neat look.

The neatness of this hairstyle makes it suit any event that comes your way. It can be official or casual. Above all; your hair should conjoin with your beard on both sides of the head.

20. Patchy Beard with Side Swept Long Hair

Here, your hair should conjoin with your beard. A section of your beard should conjoin with your moustache. Additionally, your beards should increases in length as it stretches downwards.

Draw a line on the left side of your mid head. This line separates your left sideways hair from the remaining front view hair.

Comb your left sideways hair behind your left ear. The remaining front view hair should be directed towards the right side of the head.

21. Dutch Style With Patchy Beard

Men have an option of combing their hair in different directions. The layered look combined with moustache and beard on cheeks describe this haircut.

This haircut requires regular trim especially on the beard. Short beard is easy to maintain. Shaping hair edges isn’t recommended on both the hair and on your beard.

22.Faded Side Hair With Low Beard

This is among the beard styles for patchy beard on this list with a fade look. The second fade determines the length of your beard, but it should be low.

Moustache growth is also encouraged on this haircut. The fade look requires regular trim in order to maintain this look. You can shape hair line if you favor the look.

23. Curly Scruffy Haircut With Patchy Beard

You should have lengthy hair that can incorporate a curly look. The curly look depends on an individual’s preference.

Also, moustache, chin beard and cheek beard are also encouraged. This is mostly a casual look but you can easily come up with an official look. Most types of hair can attain this haircut.

24. Systematic Fade With Low Patchy Beard

This official look never gets old or out-fashioned. The side fade on both sides and at the back brings out that cute look.

This is another beard styles for patchy beard that recommends low beard. That’s why men who choose this hairstyle have an easy time maintaining it.

25. Simple Cheek Beard And Moustache

Your hair should conjoin with cheek beard on both sides and extend to your chin. The moustache should also conjoin with your cheek beard.

Spice up this look by shaping the hair edges and the beard edges. Low beard are easy to maintain, especially if you have a busy schedule.

26. Curly Highlighted Look with Patchy Beard

Give your long hair a curly look. Proceed with brown highlights around the head. This combination makes anyone admire you while on the move.

You are also encouraged to grow beard including the moustache. Trim low your beard for a neat look. hair can be slicked on any direction. What are you waiting for? Grow your hair and try out this spectacular look.

27. Van Dyke Hair Part And Beard

This haircut favors men looking for a simple and easy to maintain haircut. The low trim beard allows this hairstyle to be categorized into an official look.

This haircut is mostly recommended for men with thick hair. You can choose to part your hair on either the right or left side of the head.

28. Curly Hair With Fade And Beard

The curly look and side fade makes this haircut be listed among the top looks on this lost. You should also trim low your moustache and beard at large.

There is no limit on the events you can attend with this haircut, be it official or casual. To maintain this look, you might require weekly maintenance.

29. Sparse and Short Beard Style

The systematic fade from top towards the back and both sides bring out an urban look. This haircut favors individuals who prefer low beard.

Most men find this haircut comfortable. Furthermore, anyone whose hair at attained the recommended length can easily try out this hairstyle.

30. Bristly Look With Patchy Beard

The spiky look on the head gets noticed even from a distance. A layered look is the easiest way of attaining the spiky look. There is a fade out on both sides of the head and on the back of the head.

This haircut recommends maintaining low beard. Ensure your hair can form the spiky look before trying out this hairstyle.